Development of improved clay brick products using plastic fibres

A project financed by the Region of Southern Denmark and The Danish Agency for Science and Innovation.

This was a development project initiated by the company Danish Fibre Production in Varde.

The project work was carried out in collaboration between a series of companies with the goal of improving clay brick products by the addition of plastic fibres.

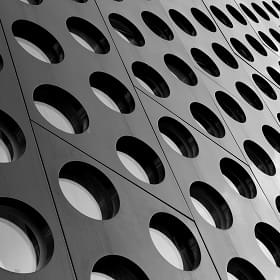

The expected effect of adding plastic fibres to clay, which was subsequently kiln fired, was:

- Achievement of a capillary structure giving a weight reduction in the finished product.

- Lower percentage of waste in the production.

The reason for the latter is that fewer bricks explode during firing due to trapped steam.

The lower percentage of waste gives rise to a number of advantages such as lower CO2 emissions, increased profits in the value chain, as well as better export opportunities due to an improved product.

For further information, please contact:

For further information, please contact:

- Bente Nedergaard Christensen

- Polymer Specialist - Project Manager

- B.Sc. Chem. Eng., B.Sc. in Lab. Tech.